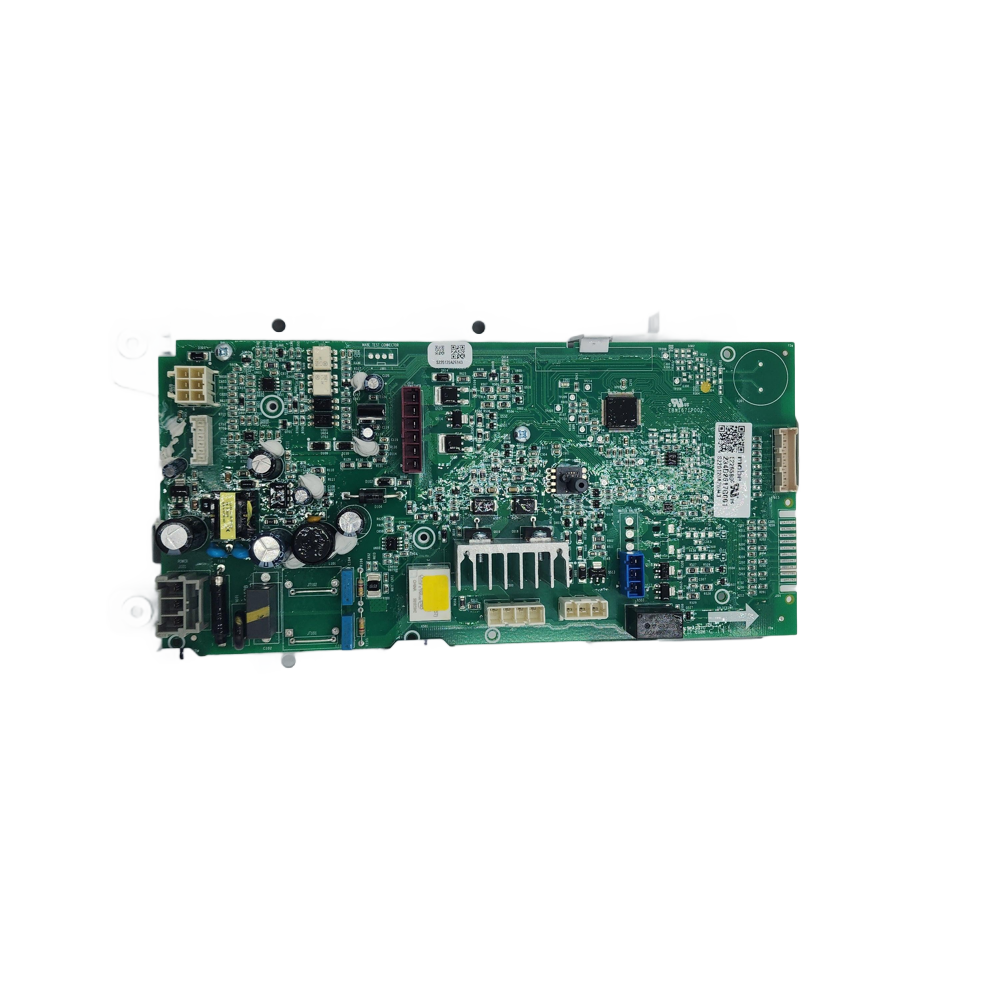

- Document all 8-12 wire harnesses with detailed photos and create a comprehensive connector map before disconnecting. Take high-quality photos of each electrical connector from multiple angles, capturing the connector type, orientation, wire colors, and pin positions. Create a detailed connector map or reference guide with labels for each connector function (motor, water inlet valves, drain pump, door lock, temperature sensors, pressure switch, user interface, power supply, etc.). Number each connector (1-12) with masking tape as you photograph it. This documentation is critical for ensuring correct reconnection and avoiding costly mistakes.

- Use a systematic numbering and labeling approach for all connectors. As you photograph each connector, immediately label it with masking tape indicating its number (1-12), function, and original position on the control board. Keep the labeled connectors organized in numerical order as you disconnect them. This prevents confusion during reassembly and ensures correct connector placement.

- Verify connector orientation and pin alignment before reconnection. Some connectors can be inserted in the wrong orientation, which will prevent proper board operation or cause component damage. Compare each connector orientation to your reference photos before reconnecting. The connector should insert smoothly without forcing. If a connector does not insert smoothly, stop and verify the orientation is correct. Never force a connector onto the board.

- Test the old control board with a multimeter before ordering a replacement. Use a multimeter set to voltage mode to test for power at the control board power input connector. A functioning board should show 120V AC at the power input connector. Zero voltage indicates a power supply failure or burned-out board. Test the motor output with the washer set to wash cycle—you should see voltage at the motor connector. Test the water inlet valve outputs—you should see voltage when the washer is filling. Testing prevents unnecessary board replacement and identifies upstream power supply issues.

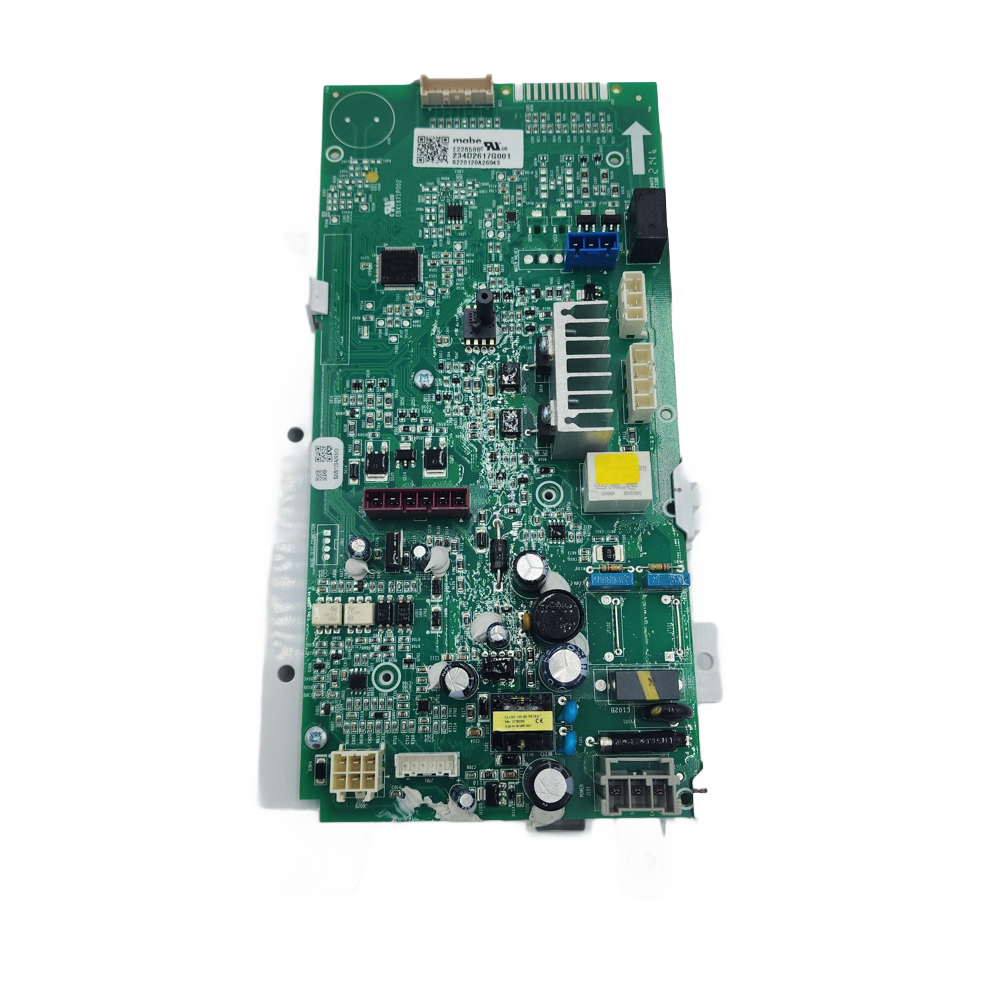

- Inspect all capacitors for signs of failure before concluding the board is faulty. Electrolytic capacitors commonly fail in control boards, causing loss of functions or erratic operation. Look for bulging, leaking, or burned capacitors on the board. Bulging or leaking capacitors indicate board failure and require replacement. A single failed capacitor can disable entire circuit sections. Capacitors typically fail after 5-10 years of operation.

- Inspect all relays and triacs for signs of burning or corrosion. Relays control motor and pump activation, and triacs control motor speed. Look for burned or discolored relays and triacs on the board. Burned components indicate board failure and require replacement. Relay or triac failure will prevent proper component activation even with a functioning microprocessor.

- The control board manages both 120V AC and 240V AC circuits simultaneously. The control board receives 120V AC for logic and display functions and may receive 240V AC for motor control on some models. Verify both voltages are present at the power input connectors before concluding the board is faulty. Loss of either voltage will prevent proper operation.

- Allow the washer to complete a full cycle before evaluating performance. After installing the new control board, run a complete wash cycle (approximately 30-45 minutes) to verify all functions operate properly throughout the entire cycle. Do not interrupt the cycle. Monitor the washer throughout the cycle to verify filling, washing, draining, and spinning all function correctly.

- The control board communicates with multiple sensors throughout the washer. The pressure switch monitors water level, temperature sensors monitor water temperature, and other sensors monitor cycle progress. If the washer does not operate properly after board replacement, verify all sensors are connected and functioning correctly by testing with a multimeter.

- This repair is cost-effective compared to washer replacement. The cost of control board replacement ($120-180) is far less than the cost of a new washer ($1,200-3,000+). Replace the control board promptly when failure is detected to prevent the need for expensive washer replacement and to restore proper washer operation and all electronic functions.

Whirlpool refrigerator replacement parts, Frigidaire refrigerator replacement parts, GE refrigerator replacement parts, Kenmore refrigerator replacement parts, KitchenAid refrigerator replacement parts, LG refrigerator replacement parts, Maytag refrigerator replacement parts, Whirlpool refrigerator drawers and glides replacement, Whirlpool dishwasher replacement parts, GE dishwasher replacement parts, KitchenAid dishwasher replacement parts, Maytag dishwasher replacement parts, Frigidaire dishwasher replacement parts, Kenmore dishwasher replacement parts, Whirlpool washer replacement parts, GE washer replacement parts, Maytag washer replacement parts, Kenmore washer replacement parts, LG washer replacement parts, Whirlpool dryer replacement parts, GE dryer replacement parts, Maytag dryer replacement parts, Kenmore dryer replacement parts, LG dryer replacement parts, Whirlpool range replacement parts, GE range replacement parts, Whirlpool stove replacement parts, GE stove replacement parts, GE oven replacement parts, GE microwave replacement parts, buy Whirlpool refrigerator parts online, buy GE dishwasher parts online, replacement Kenmore washer parts for sale, buy Maytag dryer parts, LG washer replacement parts online, KitchenAid refrigerator parts for sale, Whirlpool stove and range replacement parts