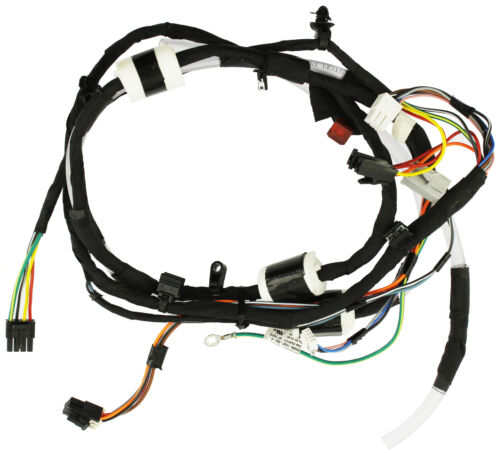

Diagnose before replacing—wire harnesses are expensive. Before ordering a $100+ wire harness, use a multimeter to test continuity through each wire in the harness. With power disconnected, test from the control board connector to each component connector. A good wire should show near-zero resistance (continuity). An open circuit (infinite resistance) indicates a broken wire. Also inspect every connector for corrosion, bent pins, or melted plastic. Sometimes cleaning or repairing a single connector or wire splice can save you from replacing the entire harness.

Water damage is the #1 harness killer. If your washer leaked or overflowed, water likely entered wire connectors and caused corrosion. Even after drying, corroded connectors create high resistance that causes overheating and component failure. When replacing a harness due to water damage, also inspect and address the source of the leak (pump seal, hose, inlet valve, tub seal). Otherwise your new harness will fail the same way.

Routing and securing prevents repeat failures. The new harness must be routed away from moving parts (drum, motor pulley, agitator), hot components (motor, pump), and sharp edges. Use protective grommets where wires pass through metal openings. Secure the harness with clips or zip ties every 8-12 inches to prevent movement and chafing. A poorly routed harness will fail within months due to wire damage from vibration and movement.

Connector orientation and pin alignment matter. Most connectors are keyed and can only connect one way, but some can be forced on incorrectly or offset by one pin position. Always compare your installation to reference photos. An incorrectly connected harness sends voltage to the wrong circuits and can destroy the control board, motor controller, or other expensive components instantly when power is applied.

Test before full reassembly. After connecting the new harness but before reinstalling all panels, restore power and run a quick test cycle. Verify all functions work correctly: filling, agitating/tumbling, draining, spinning, and locking. This allows you to catch any connection errors before you've fully reassembled the washer. If something doesn't work, recheck your connections immediately.

Address the root cause of harness failure. Wire harnesses don't fail randomly—something caused the damage. Common causes include water leaks (corrodes connectors), excessive vibration (chafes wires), overheating components (melts insulation), or manufacturing defects. Identify and fix the underlying problem or your new harness will fail prematurely. If the washer has been leaking, repair the leak source. If wires chafed, improve routing and add protective sleeving.

Strain relief at connectors is critical. When routing the new harness, leave 2-3 inches of slack at each connector location. This prevents stress on the connector pins when the washer vibrates or components move slightly. Tight, stretched wires pull on connectors and cause intermittent connections or broken pins. Proper slack extends harness life significantly.

Whirlpool refrigerator replacement parts, Frigidaire refrigerator replacement parts, GE refrigerator replacement parts, Kenmore refrigerator replacement parts, KitchenAid refrigerator replacement parts, LG refrigerator replacement parts, Maytag refrigerator replacement parts, Whirlpool refrigerator drawers and glides replacement, Whirlpool dishwasher replacement parts, GE dishwasher replacement parts, KitchenAid dishwasher replacement parts, Maytag dishwasher replacement parts, Frigidaire dishwasher replacement parts, Kenmore dishwasher replacement parts, Whirlpool washer replacement parts, GE washer replacement parts, Maytag washer replacement parts, Kenmore washer replacement parts, LG washer replacement parts, Whirlpool dryer replacement parts, GE dryer replacement parts, Maytag dryer replacement parts, Kenmore dryer replacement parts, LG dryer replacement parts, Whirlpool range replacement parts, GE range replacement parts, Whirlpool stove replacement parts, GE stove replacement parts, GE oven replacement parts, GE microwave replacement parts, buy Whirlpool refrigerator parts online, buy GE dishwasher parts online, replacement Kenmore washer parts for sale, buy Maytag dryer parts, LG washer replacement parts online, KitchenAid refrigerator parts for sale, Whirlpool stove and range replacement parts