GE: PHP9036SJSS, PHP9036DJBB, PHP9036DJWW, PHP9036SLSS, PHP9036DLBB, PHP9036DLWW, PHS930SLSS, PHS930YPFS, PHS930BLTS, PHS930SLTS

GE (continued): PHS930YPFS, PHS930BLTS, PHS930SLTS, PHP960DMBB, PHP960DMWW, PHP960SMSS, PHP960DPBB, PHP960DPWW, PHP960SPSS, PHS920SFSS

GE (continued): PHS920YPFS, PHS920BLTS, PHS920SLTS, PHP9030SJSS, PHP9030DJBB, PHP9030DJWW, PHP9030SLSS, PHP9030DLBB, PHP9030DLWW, PHP9030DPBB

GE (continued): PHP9030DPWW, PHP9030SPSS, PHP9030SLSS, PHP9024SJSS, PHP9024DJBB, PHP9024DJWW, PHP9024SLSS, PHP9024DLBB, PHP9024DLWW, PHP9024DPBB

Hotpoint: RAS200DMWW, RAS200DMBB, RAS200DMCC, RAS300DMWW, RAS300DMBB, RAS300DMCC, RAS400DMWW, RAS400DMBB, RAS400DMCC, RAS500DMWW

Hotpoint (continued): RAS500DMBB, RAS500DMCC, RAS600DMWW, RAS600DMBB, RAS600DMCC, RAS700DMWW, RAS700DMBB, RAS700DMCC, RAS800DMWW, RAS800DMBB

Kenmore: 79572022010, 79572022011, 79572022012, 79572022013, 79572022014, 79572022015, 79572022016, 79572022017, 79572022018, 79572022019

Haier: HCR2250IDS, HCR2250IDW, HCR2250ICS, HCR2250ICW, HCR3250IDS, HCR3250IDW, HCR3250ICS, HCR3250ICW, QAS740IMSS, QAS740INSS

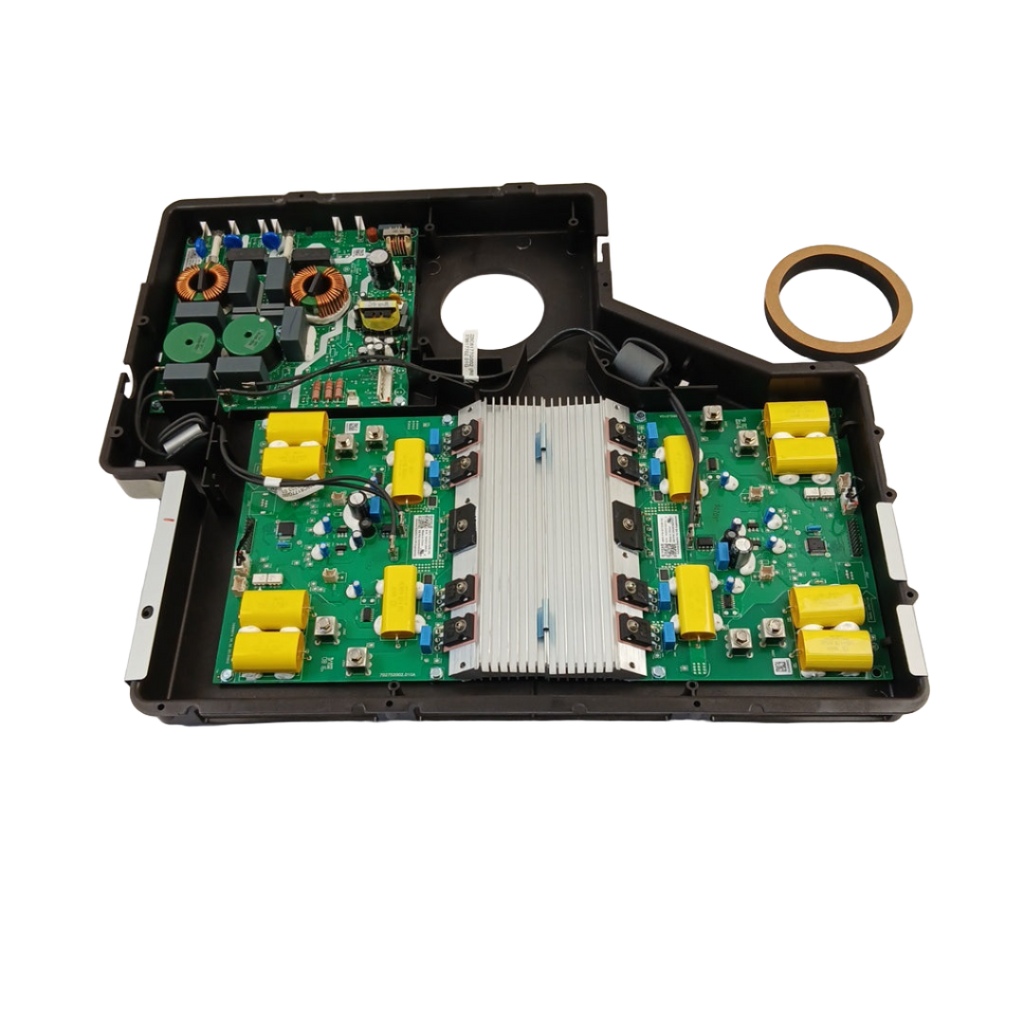

Note: This is a partial list. This induction control assembly is used in many GE-manufactured induction ranges and wall ovens built between 2015-2024. Verify your specific model number for compatibility before ordering. Induction control assemblies are model-specific—using an incompatible assembly will cause malfunction.