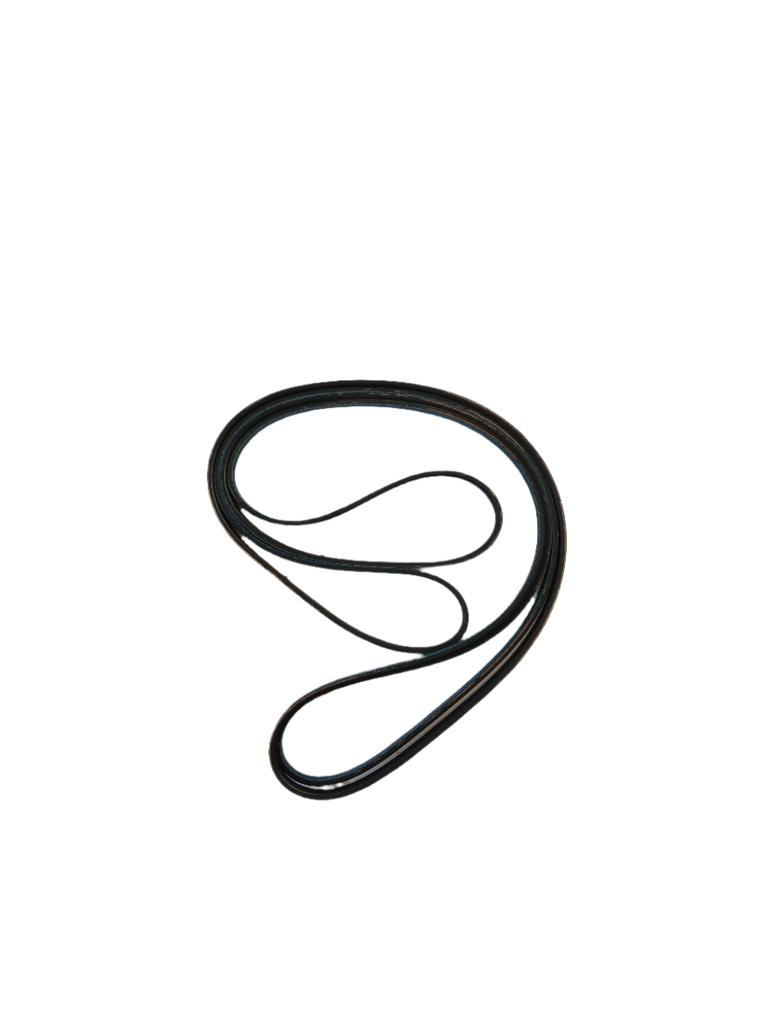

D511255P Dryer Drum Belt

The D511255P is a genuine OEM Speed Queen dryer drum belt designed for Speed Queen, Amana, Alliance, Frigidaire, and related brand electric and gas dryers. This critical component wraps around the dryer drum and connects it to the motor pulley, allowing the drum to rotate during the drying cycle. The dryer drum belt is essential for proper dryer function—without a functioning belt, the drum cannot rotate and the dryer will not work. The D511255P is a 99-inch long, 5-rib rubber belt with a flat design that routes around the drum and motor pulley. The belt is rated for continuous operation and provides reliable, long-lasting drum drive performance. The dryer drum belt is a complete assembly that includes all components necessary for installation. The dryer drum belt is constructed from premium materials including a high-durability rubber compound (provides excellent grip and wear resistance), reinforced fiber core (provides tensile strength and prevents stretching), 5-rib design (increases surface contact and grip on motor pulley), flat profile with 4 grooves (matches the pulley grooves for secure routing), and optimized thickness and width (99 inches long, 5 ribs, 4 grooves). The D511255P features a flat belt design that routes around the outer edge of the drum and the motor pulley. Unlike serpentine belts that route around multiple pulleys, this belt connects directly from the drum to the motor pulley, providing direct mechanical connection that allows the motor to rotate the drum. The D511255P replaces older part numbers including 511255P, 435P3, 510178, 511255, 59174, D511255, AP6285392, PS12195395, EAP12195395, and similar drive belts and features improved rubber compound formulation for better durability and longer lifespan (40% longer than previous generation), enhanced fiber core for superior tensile strength and resistance to stretching, optimized rib design for better pulley grip and reduced slipping, improved groove design for better alignment and reduced wear, and optimized length and width for smooth, quiet drum rotation across all compatible dryer models. The dryer drum belt operates through mechanical transmission: during the drying cycle, the dryer motor rotates the motor pulley; the motor pulley is connected to the drive belt; the belt rotates around the motor pulley and drum; the belt's grip on the drum causes the drum to rotate; the drum rotates at approximately 50-70 RPM (depending on cycle speed); the belt transmits rotational force from the motor to the drum; when the drying cycle ends, the motor stops and the drum stops rotating. Common failure causes include normal wear from age and continuous operation (typical belt lifespan 5-10 years with average use), mechanical wear from friction causing the belt to thin and fray, drum bearing wear causing increased friction and belt wear, motor pulley wear causing belt slipping, lint and debris accumulation on the belt causing friction and wear, physical damage from foreign objects in the dryer, manufacturing defects, or premature failure from low-quality replacement belts. When the dryer drum belt fails, symptoms include dryer drum not rotating (belt broken or slipped off), loud squeaking or squealing noise from dryer (belt slipping or fraying), loud thumping or banging noise from dryer (belt misaligned or slipping), dryer running but clothes not drying (drum not rotating), visible wear or fraying on belt surface (mechanical wear), burning smell from dryer (belt friction or overheating), or complete dryer failure (belt broken, motor cannot rotate). The D511255P is a direct replacement drive belt that provides reliable, smooth drum rotation for efficient drying performance and long service life. IMPORTANT: This is a 99-inch long belt with 5 ribs designed for specific Speed Queen/Amana/Alliance dryer models. Verify your dryer model uses this belt length and rib configuration before ordering. CRITICAL: Always unplug the dryer before working on internal components to prevent electrical shock and accidental drum rotation. This repair involves accessing the dryer drum and internal components—exercise caution to prevent injury.

Part Number D511255P replaces 511255P

Supported Models:

ADE30RGS171TW01, ADE32FSS431AN01, ADE32FSS431NN22, ADE32FSS541RN01, ADE3LRGS171TW01, ADE3SRGS173CW01, ADE3SRGS173TW01, ADE3SRGS175CW01, ADE3SRGS175CW14, ADE3SRGS175TW01, ADE3TFWS431AW01, ADE3TRGS451LW22, ADE3TRWS431AW01, ADE3TRWS431NW22, ADE3TRWS431NW29, ADE3TRWS461AW01, ADE41FSS171TN01, ADE41FSS171TN03, ADE4BFGS171TW01, ADE4BRGS171TW01, ADE4BRGS171TWAH, ADE4BRGS175CW01, ADE4BRGS175CW14, ADE4BRGS175TW01, ADEE8RGS173CW01, ADEE8RGS173TW01, ADEE9BGS173CW01, ADEE9BGS173TW01, ADEE9BGS175CW01, ADEE9BGS175CW14, ADEE9BGS175TW01, ADEE9BSS173CN01, ADEE9BSS173TN01, ADEE9BSS175CN01, ADEE9BSS175CN14, ADEE9BSS175TN01, ADEE9RGS173CW01, ADEE9RGS173TW01, ADEE9RGS175CW01, ADEE9RGS175CW14, ADEE9RGS175TW01, ADG30RGS111TW01, ADG32FSS301AN01, ADG3LRGS111TW01, ADG3SRGS113CW01, ADG3SRGS113TW01, ADG3SRGS115CW01, ADG3SRGS115CW14, ADG3SRGS115TW01, ADG3TFWS301AW01, ADG3TRWS301AW01, ADG41FSS111TN01, ADG41FSS111TN03, ADG4BFGS111TW01, ADG4BRGS111TW01, ADG4BRGS111TWAH, ADG4BRGS115CW01, ADG4BRGS115CW14, ADG4BRGS115TW01, ADGE8RGS113CW01, ADGE8RGS113TW01, ADGE9BGS113CW01, ADGE9BGS113TW01, ADGE9BGS115CW01, ADGE9BGS115CW14, ADGE9BGS115TW01, ADGE9BSS113CN01, ADGE9BSS113TN01, ADGE9BSS115CN01, ADGE9BSS115CN14, ADGE9BSS115TN01, ADGE9RGS113CW01, ADGE9RGS113TW01, ADGE9RGS115CW01, ADGE9RGS115CW14, ADGE9RGS115TW01, AES17AWF, AES20AWF, AES28AWF, AES28AWF1500, AES68AWF, AES68AWF1500, AEZ17A*F1702, AEZ28A*F1702, AEZ68A*F1702, AGS17AWF, AGS20AWF, AGS28AWF, AGS68AWF, AGZ17A*F1102, AGZ28A*F1102, AGZ68A*F1102, ASE30FGW171TW01, ASEE8AGW173TW01, ASG30FGW111TW01, ASGE8AGW113TW01, ATE50FGP171TW01, ATE50FWP431AW01, ATEE9AGP173TW01, ATEE9ASG453NW36, ATEE9ASG455NW36, ATEE9ASP133DN04, ATEE9ASP133DW04, ATEE9ASP175TW01, ATEE9ASP283CW01, ATEE9ASP285CW01, ATEE9ASP285CW14, ATEE9ASP433XW34, ATEE9ASP435XW34, ATEE9ASP453LW26, ATEE9ASP455LW01, ATEE9ASP543DN04, ATEE9ASP543DW04, ATEE9ASP545DW04, ATEE9AWP433AW01, ATEE9AWP435AW01, ATG50FGP111TW01, ATG50FWP301AW01, ATGE9AGP113TW01, ATGE9ASP093CW01, ATGE9ASP095CW01, ATGE9ASP095CW14, ATGE9ASP115TW01, ATGE9ASP123DN04, ATGE9ASP123DW04, ATGE9ASP125DW04, ATGE9ASP303XW01, ATGE9ASP303XW26, ATGE9ASP305XW01, ATGE9ASP543DN04, ATGE9ASP543DW04, ATGE9ASP545DW04, ATGE9AWP303AW01, ATGE9AWP305AW01, ATHE9ASP453NW29, ATHE9ASP455NN29, ATHE9ASP455NW29, BD3NGBGS403UW01, BD3NGBSS403UN01, BD3NLBGS403UW01, BD3NLBSS403UN01, BD3NXAGS403UW01, BDE30FGS171CW01, BDG30FGS111CW01, BDGNGBGS303EW01, BDGNLBGS303EW01, BDGNXAGS303EW01, BTE50FSP171TW01, BTE50FSP281CW01, BTEE6ASP173TW01, BTEE6ASP283CW01, BTG50FSP091CW01, BTG50FSP111TW01, BTGE6ASP093CW01, BTGE6ASP113TW01, CDE3LRGS171CW01, CDE4BFGS171CW01, CDG3LRGS111CW01, CDG4BFGS111CW01, CES68AWF, CES68AWF1500, CEZ68A*F1702, CGS68AWF, CGZ68A*F1102, CTS97AWN, CTS97AWN1500, CTS99AWN, CTSA7AWN, CTSA7AWN1500, CTSA9AWN, DDE30RGS173CW01, EDE3TRWS543PW01, FDE3TRGS301NW10, FDE3TRGS401NW22, FDG3TRGS301NW10, FEN16A*G4018, FEN17A*G3018, FEN17A*G4018, FES16A*G4018, FES17A*F3300, FES17A*F4350, FEU17A*F1702, FEZ17A*F1702, FGN16A*M3013, FGN17A*M3013, FGS17A*F3060, FGZ17A*F1102, FTE50FSP301NW01, FTE50FSP301NW10, FTEE5ASP303NW10, FTEE5ASP303ZW01, FTG50FSP301NW10, FTGE5ASP303NW10, HDENEAGS153CW01, HDENEAGS173CW01, HDENERGS153CW01, HDENERGS173CW01, HDENXAGS153CW01, HDENXAGS173CN01, HDENXAGS173CW01, HDENXAGS543DW01, HDENXAGW173CN01, HDENXRGS153CW01, HDENXRGS173CW01, HDENYAGS153CW01, HDENYAGS173CW01, HDENYBGS173CW01, HDENYRGS153CW01, HDENYRGS173CW01, HDGNEAGS113CW01, HDGNERGS113CW01, HDGNXAGS113CN01, HDGNXAGS113CW01, HDGNXAGS123DW01, HDGNXAGS543DW01, HDGNXAGW113CN01, HDGNXRGS113CW01, HDGNYAGS113CW01, HDGNYBGS113CW01, HDGNYRGS113CW01, JDEJEAGW303EW01, JDEJGAGW303EW01, JDEJGASW303EN01, JDEJGBGW303EW01, JDEJGBSW303EN01, JDEJRAGW303EW01, JDEJXAGW303EW01, JDGJEAGW303EW01, JDGJGAGW303EW01, JDGJGASW303EN01, JDGJGBGW303EW01, JDGJGBSW303EN01, JDGJRAGW303EW01, JDGJXAGW303EW01, KES18AWF, KES18AWF1500, KGS18AWF, LDE3TRGS171CW01, LDE3TRGS451NW22, LDE3TRGS461NW22, LDE3TRGS551NW22, LDE3TRWS331TW05, LDE3TRWS541NW22, LDG3TRGS111CW01, LDG3TRWS111TW05, LDL3TRWW301NW22, LEB07A*F1709, LED17A*F1700, LEG37A*F4350, LEH37A*F3300, LEK37A*F4350, LEN27A*G3008, LEN27A*G3018, LEN27A*G4008, LEN27A*G4018, LEN27A*G99M3, LEN37A*G3018, LEN37A*G4018, LES17A*F3000, LES17A*F3007, LES17A*F3022, LES17A*F4500, LES17A*M4588, LES27A*G3018, LES27A*G4000, LES27A*G4018, LES27A*G4500, LES27A*G4518, LES28A*G4018, LES33A*F4562, LES37A*F3000, LES37A*F3028, LES37A*F3300, LES37A*F3327, LES37A*F4350, LES37A*F5412, LES37A*G3018, LES37A*G4018, LET57A*F1700, LET67A*F1700, LET68A*F1700, LEY47A*F1709, LEZ27A*F1502, LEZ27A*F1702, LEZ27A*G3018, LEZ27A*G4018, LEZ37A*F1702, LEZ37A*F3000, LEZ37A*F3300, LEZ37A*G3018, LEZ37A*G4018, LEZ37A*G5618, LEZ57A*F1702, LEZ67A*F1702, LGG37A*F3058, LGH37A*F1182, LGH37A*F5423, LGK37A*F3058, LGK37A*F3060, LGN27A*F3060, LGN27A*M3008, LGN27A*M3013, LGN37A*M3013, LGS17A*F3020, LGS17A*F3081, LGS17A*K1180, LGS17A*M3020, LGS17A*M3082, LGS27A*M3013, LGS27A*M3080, LGS37A*F3000, LGS37A*F3022, LGS37A*F3028, LGS37A*F3058, LGS37A*F3060, LGS37A*F3080, LGS37A*F5412, LGS37A*F5423, LGS37A*G3013, LGS37A*G3080, LGS37A*M3013, LGS37A*M3080, LGS38A*M3013, LGS38A*M3020, LGS40A*M3020, LGT57A*F1100, LGT68A*F1100, LGY47A*F1109, LGZ27A*F1102, LGZ27A*M3013, LGZ37A*F1102, LGZ37A*F3000, LGZ37A*G3013, LGZ37A*M3013, LGZ57A*F1102, LGZ67A*F1102, LTE50FGP541NW23, LTEA5FSP153TW01, LTEA5FSP153TW04, LTEA5FSP173TW01, LTEA5FSP173TW04, LTEE5AGP133ZW30, LTEE5ASP133FW01, LTEE5ASP153TW01, LTEE5ASP155TW01, LTEE5ASP173TW01, LTEE5ASP175TW01, LTEE5ASP283CW01, LTEE5ASP285CW01, LTEE5ASP293CW01, LTEE5ASP295CW01, LTEE5ASP303WW01, LTEE5ASP303WW37, LTEE5ASP303ZW01, LTEE5ASP333NW01, LTEE5ASP433AW01, LTEE5ASP433AW12, LTEE5ASP453VW26, LTEE5ASP543NW01, LTEE5ASP543NW23, LTEE5ASP543RW01, LTEE5ASP553KW01, LTEE5FSP175TW01, LTG50FSP081JW01, LTGA5FSP113TW01, LTGE5ASP093CW01, LTGE5ASP095CW01, LTGE5ASP113FW01, LTGE5ASP113JW01, LTGE5ASP113TW01, LTGE5ASP115TW01, LTGE5ASP303AW01, LTGE5ASP303AW12, LTGE5FSP115TW01, LTKA6A*N4350, LTL50FGP541NW23, LTLE5ASP303NW35, LTLE5ASP543NW23, LTME5ASP543KW01, LTS87A*H, LTS87A*H1500, LTS89A*H, LTSA7A*N, LTSA7A*N1500, LTSA7A*N2989, LTSA7A*N3000, LTSA7A*N3300, LTSA7A*N4350, LTSA7A*N4351, LTSA9A*N, LTSA9A*N1180, LTSA9A*N3000, LTSA9A*N3060, LTSA9A*N3061, LTU87A*H, LTU89A*H, LTUA7A*N, LTUA7A*N2802, LTUA9A*N, LTZ87A*H, LTZ87A*H2802, LTZ89A*H, LTZ89A*H0902, LTZA7A*N, LTZA7A*N2802, LTZA9A*N, LTZA9A*N0902, MDE3TRWS331TW06, MDG3TRWS111TW06, ND3NLBGS403NW22, ND3NLBGS403ZW01, ND3NLBSS403UN01, ND3NXASS403UN01, NDENXAGS303UW01, NDGNXAGS303EW01, PD3JGBGS403UG01, PD3JXAGS403UG01, PDEJGBGS303UG01, PDEJGBGS543ZG01, PDEJXAGS434AG01, PDGJGBGS303UG01, PDGJGBGS543ZG01, PDGJXAGS303UG01, PDGJXAGS304AG01, PDGJXAGS543ZG01, PTEE3FSP173TG01, PTEE3FSP175TG01, PTEE3FSP283CG01, PTEE3FSP285CG01, PTEE3FSP433AG01, PTGE3FSP093CG01, PTGE3FSP095CG01, PTGE3FSP113TG01, PTGE3FSP115TG01, PTGE3FSP303AG01, SDENEAGS153CW01, SDENEAGS173CW01, SDENERGS153CW02, SDENERGS173CW02, SDENXAGS153CW01, SDENXAGS173CN01, SDENXAGS173CW01, SDENXAGS433AW01, SDENXAGS543DW01, SDENXRGS153CW02, SDENXRGS173CW02, SDENXRGS433AW01, SDENXRGS433LW01, SDENYAGS153CW01, SDENYAGS173CW01, SDENYRGS153CW01, SDENYRGS173CW01, SDENYRGS303NW22, SDENYRGS303ZW01, SDGNEAGS113CW01, SDGNERGS113CW02, SDGNXAGS113CN01, SDGNXAGS113CW01, SDGNXAGS123DW01, SDGNXAGS303AW01, SDGNXAGS543DW01, SDGNXRGS113CW02, SDGNXRGS303AW01, SDGNYAGS113CW01, SDGNYRGS113CW01, SDLNXRGS303LW01, SDLNXRGS543NW23, SDLNXRGS543PW01, TD3NGBS403NW36, TTHE5ASP303NW36, TTPE5ASP303NW36, UTE50FSP171TW08, UTEE5ASP173TW01, UTEE5ASP173TW08, UTEE5ASP175TW01, UTEE5ASP175TW08, UTEE5ASP283CW01, UTEE5ASP285CW01, UTG50FSP111TW08, UTGE5ASP113TW01, UTGE5ASP113TW08, UTGE5ASP115TW01, UTGE5ASP115TW08, YDE3TRGS171CW01, YDE3TRGS301NW10, YDG3TRGS111CW01, YTEE5ASP133FW01, YTEE5ASP173TW01, YTEE5ASP175TW01, YTEE5ASP283CW01, YTEE5ASP285CW01, YTEE5ASP303NW10, YTGE5ASP093CW01, YTGE5ASP095CW01, YTGE5ASP113FW01, YTGE5ASP113TW01, YTGE5ASP115TW01, ZDE30RGS171CW01, ZDE3LRGS171CW01, ZDE3SRGS173CW01, ZDE3SRGS173FW28, ZDE41FSS171CN01, ZDE4BFGS171CW01, ZDE4BRGS171CW01, ZDEE8RGS173CW01, ZDEE8RGS543FW01, ZDEE9BGS173CW01, ZDEE9BGS543FW01, ZDEE9BSS173CN01, ZDEE9BSS543FN01, ZDEE9RGS173CW01, ZDEE9RGS543FW01, ZDG30RGS111CW01, ZDG3LRGS111CW01, ZDG3SRGS113CW01, ZDG3SRGS113FW28, ZDG41FSS111CN01, ZDG4BFGS111CW01, ZDG4BRGS111CW01, ZDGE8RGS113CW01, ZDGE8RGS113FW01, ZDGE9BGS113CW01, ZDGE9BGS113FW01, ZDGE9BSS113CN01, ZDGE9BSS113FN01, ZDGE9RGS113CW01, ZDGE9RGS113FW01