Always verify the motor and clutch are functioning before replacing the transmission. A faulty motor or worn clutch can cause symptoms that mimic transmission failure—no agitation, no spinning, or slow rotation. Before replacing the transmission, verify the motor is running during wash and spin cycles and the clutch is engaging properly. If the motor or clutch is faulty, replace those components instead of the transmission.

Test the motor coupling for wear. The motor couples to the transmission through a rubber or plastic coupling that can wear out or break. A broken coupling prevents power transfer to the transmission. Inspect the coupling carefully and replace if damaged. A worn coupling can cause slipping and slow agitation or spinning.

Inspect the transmission seals for leaks. Water intrusion is a common cause of transmission failure. Inspect all transmission seals carefully for leaks before and after installation. Any leaks must be addressed immediately to prevent water damage to the new transmission. A leaking transmission will fail prematurely.

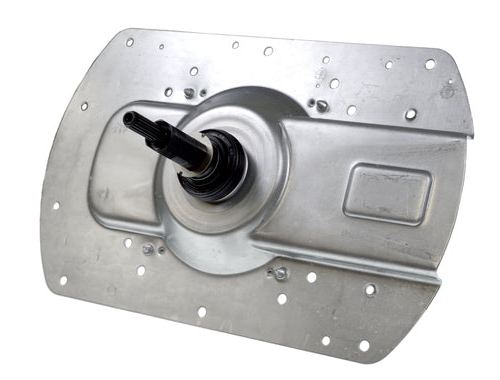

Verify proper transmission orientation during installation. The transmission must be installed in the correct orientation for the agitator and basket to function properly. Compare the new transmission position to your photos to ensure correct orientation. Incorrect orientation can prevent proper agitation or spinning.

This transmission assembly is model-specific. The WW03F00111 is designed for specific GE and Hotpoint top-load washers. Always verify your washer model number matches one of the compatible models before ordering. Using an incorrect transmission can result in non-fit or improper washer operation.

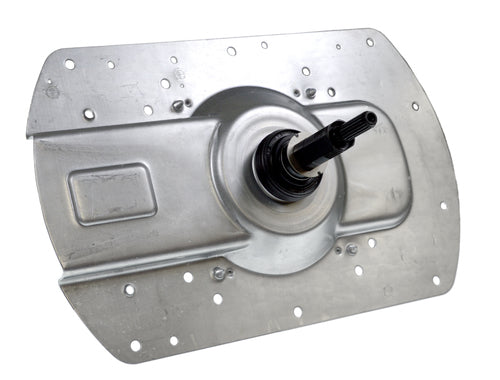

This is a complete transmission assembly. The WW03F00111 includes the transmission housing, gears, bearings, clutch mechanism, seals, and internal components. All components are pre-assembled and ready for installation. You cannot replace individual components—the entire assembly must be replaced if any part fails.

Transmission replacement is a major repair. This repair requires significant mechanical skill, specialized tools (such as socket sets, torque wrench, breaker bar, spanner wrench), and extensive knowledge of washer mechanics. If you're uncomfortable with the process, consult a professional technician. Improper installation can cause poor performance, leaks, or damage to other washer components.

Monitor the first few wash cycles after installation. After installing the new transmission, run several wash cycles and monitor for proper agitation, proper spinning, unusual noises, vibration, and oil leaks. Address any issues immediately before they affect washing performance or indicate improper installation.

Transmission failure can have multiple causes. If the new transmission doesn't solve the problem, the issue may be with the motor, clutch, control board, timer, or another component. Further diagnosis may be required to identify the root cause.

Keep the transmission dry. Water intrusion is a primary cause of transmission failure. Ensure the washer cabinet is dry and there are no active leaks before installing the new transmission. Regularly inspect the transmission area for signs of water damage or corrosion.

This repair requires professional-grade tools. Transmission installation requires a socket set, breaker bar, torque wrench, and possibly a spanner wrench. Improper torque on the basket nut can cause the basket to loosen or the transmission to shift during operation. If you don't have the proper tools, consult a professional technician.

Transmission oil should not be added unless necessary. Most new transmissions come pre-lubricated from the factory. Do not add oil unless the transmission is leaking or the installation instructions specifically require it. Overfilling can cause leaks and poor performance.

If multiple transmissions fail prematurely, check for root causes. If the transmission fails again shortly after replacement, there may be an underlying problem causing premature failure. Common causes include water leaks, motor coupling failure, control board malfunction, or overloading. Identify and fix the root cause to prevent repeated transmission failure.

Verify the mechanical timer or control board is functioning. GE and Hotpoint washers use either mechanical timers or electronic control boards to shift the transmission between agitate and spin modes. If the transmission doesn't shift properly, verify the timer or control board is sending proper signals. Test with a multimeter if necessary.

Check the basket drive block for wear. The basket drive block connects the basket to the transmission shaft. A worn drive block can cause slipping or poor spin performance. Inspect the drive block carefully and replace if worn or damaged.

Inspect the transmission input shaft for damage. The motor couples to the transmission input shaft. A damaged or worn input shaft can cause poor power transfer or grinding noises. Inspect the shaft carefully and replace the transmission if damage is present.

- Washer does not spin (basket doesn't rotate during spin cycle)

- Washer does not agitate (agitator doesn't move during wash cycle)

- Washer stuck in one mode (agitates but won't spin, or vice versa)

- Grinding, squealing, or clunking noises from transmission area

- Excessive vibration during spin cycles

- Agitator or basket rotates slowly or inconsistently

- Oil or grease leaking from transmission area

- Washer stops mid-cycle

- Basket is difficult to rotate by hand

- Transmission makes loud banging or knocking noises

- Washer completes wash cycle but skips spin cycle

- Agitator moves weakly or inconsistently

- Basket spins intermittently (starts and stops randomly)

- Transmission does not shift

Whirlpool refrigerator replacement parts, Frigidaire refrigerator replacement parts, GE refrigerator replacement parts, Kenmore refrigerator replacement parts, KitchenAid refrigerator replacement parts, LG refrigerator replacement parts, Maytag refrigerator replacement parts, Whirlpool refrigerator drawers and glides replacement, Whirlpool dishwasher replacement parts, GE dishwasher replacement parts, KitchenAid dishwasher replacement parts, Maytag dishwasher replacement parts, Frigidaire dishwasher replacement parts, Kenmore dishwasher replacement parts, Whirlpool washer replacement parts, GE washer replacement parts, Maytag washer replacement parts, Kenmore washer replacement parts, LG washer replacement parts, Whirlpool dryer replacement parts, GE dryer replacement parts, Maytag dryer replacement parts, Kenmore dryer replacement parts, LG dryer replacement parts, Whirlpool range replacement parts, GE range replacement parts, Whirlpool stove replacement parts, GE stove replacement parts, GE oven replacement parts, GE microwave replacement parts, buy Whirlpool refrigerator parts online, buy GE dishwasher parts online, replacement Kenmore washer parts for sale, buy Maytag dryer parts, LG washer replacement parts online, KitchenAid refrigerator parts for sale, Whirlpool stove and range replacement parts